Project Showcase : Mixed-Use Property in Arizona

From the Nightmare on Elm Street to Whispering Pines

Project Summary

A high-end mixed-use property in the Greater Phoenix area was experiencing an extreme screeching noise in its parking garage. The noise was enough to disturb adjacent businesses and residences. After a couple layers of QuietCoat® Acoustical Coating, the noise and vibration were drastically reduced —in essence, going from a screaming, almost overwhelming situation to a tranquil, peaceful environment.

The Challenge

The Challenge

The company managing the development of the property needed to eliminate the harsh wind-induced noise in the parking garage. During moderate wind events (winds at 10-35 mph), the aluminum panels in the garage exhibited a shrill, resonant shriek. The Principal of the development firm contacted acoustic consultants all over the world to help resolve the noise problem without success until he reached out to MD Acoustics, LLC in Chandler, AZ.

The Solution

Mike Dickerson, Principal for MD Acoustics, selected QuietCoat® Acoustical Coating as the solution. “We went through a series of iterations to determine the best solution,” said Dickerson. “At the end of the day, we selected QuietCoat® as the most cost effective and best sound damping option based on project constraints.” Prior to moving forward with the acoustical coating, the acoustical engineering firm tested the product on a mockup of the panel causing the noise and found that QuietCoat® mitigated the resonance.

The Results

Using QuietCoat® Acoustical Coating, MD Acoustics was able to eliminate the problem and silence the building, even during the windy monsoon season where wind speeds can reach 70+ miles per hour, according to Dickerson.

“With just two coats of QuietCoat® applied to the inside of the metal panels causing the vibration, the harsh noise was almost completely eliminated,” said the Principal of the development company. “QuietCoat® worked like a charm. We avoided a major nuisance for our tenants and helped create a more conducive environment.”

“With just two coats of QuietCoat® applied to the inside of the metal panels causing the vibration, the harsh noise was almost completely eliminated,” said the Principal of the development company. “QuietCoat® worked like a charm. We avoided a major nuisance for our tenants and helped create a more conducive environment.”

Beyond eliminating the noise, fewer coats of QuietCoat® were needed than originally thought to resolve the issue. “It was expected that multiple coats would be needed on both the inside and outside to quiet the noise,” said Dickerson. “Using only two coats on the inside saved costs and was safer for the client when applying the coating.” Since all the work was done on the interior side, there was no need to erect scaffolding or scale the outside of the structure.

“We also saved the owner a lot of money—literally salvaging the design of the building by providing QuietCoat® as the solution,” Dickerson added.

Acoustic Tests Performed

Acoustical Camera Overview

MD Acoustics performed acoustical and mechanical tests on the aluminum panels used in the garage of the mixed-use property to demonstrate the ability of QuietCoat® to solve the noise issue caused by the wind-induced panel resonance.

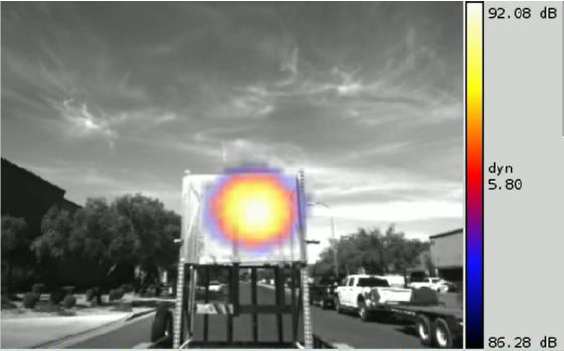

MD used acoustical beamforming techniques to measure the sound radiating from both untreated and treated panels. They used a SoundCam system to create a map of the noise while the panel was subjected to wind. The SoundCam uses microphones to map the location of noise sources in real time. This provides a visual representation of the areas of the panel that produce the most noise.

The wind-noise phenomenon was replicated by towing the aluminum panel on a trailer at 30 mph. The SoundCam was positioned near the bed of the truck at approximately 10 feet from the attached trailer and panel mount. The measurement output is a video showing a color map of the loudest noise sources within the range of the camera.

Figure 1 illustrates the SoundCam results measured for the untreated panel. It shows the color contour, the loudest noise source, at approximately 92 dB in the center of the panel.

Figure 2 shows the SoundCam results when the panel was treated with two coats of QuietCoat®. The noise from the panel has sunk beneath the noise floor and the character of that noise has shifted such that the spectrum shows no distinct tones. This illustrates the drastic difference in radiated sound (in dB) between the untreated and treated panels.

Mechanical Testing

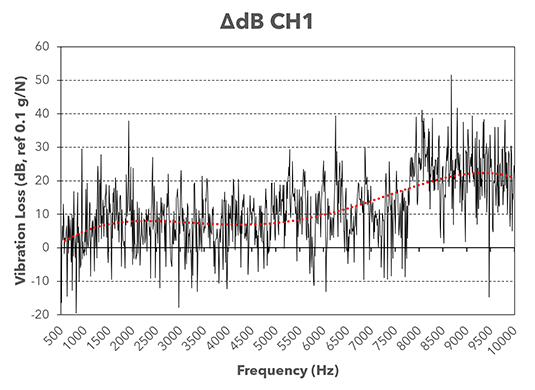

In addition to acoustical testing, MD also conducted a vibration test using a modal hammer and accelerometers to measure the frequency response of the aluminum panel. Vibration was also measured as it is the source of why sound and noise exist. When something vibrates and causes the air to make a pressure wave, we hear that pressure wave as “sound”.

Figure 3 is a measurement of the vibration of the untreated plate minus the measurement of the treated plate, resulting in a “Vibration Loss” from 500 Hz to 10,000 Hz. There were 12 different locations where the accelerometer measured the vibration on the plate. The average dB vibration loss over the entire frequency range and for all locations was 9 dB. Figure 3 shows an analysis of location 1 as an example. The results show an average 12 dB vibration loss over the entire frequency range for location 1. A peak vibration loss of 52 dB at 8,280 Hz was achieved showing significant improvements in the harsh mid- to high-frequency range where the noise issue occurred.

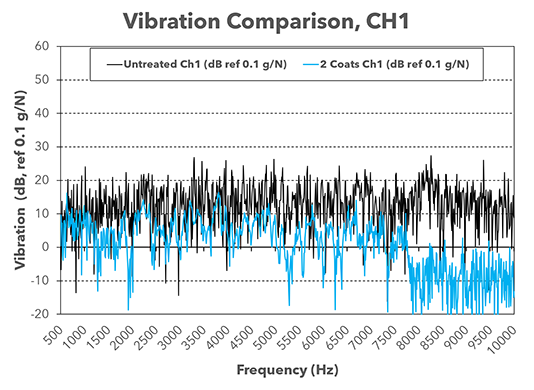

Figure 4 shows the untreated and treated panel on the same chart showing visually the significant difference between the two vibration responses.