Project Showcase : California Pacific Medical Center

Acoustical design was key objective in construction of new 274 bed hospital located in San Francisco.

Integrated Project Team Creates Cost Effective, Quiet Solution for Hospital

Project Summary

California Pacific Medical Center, a Sutter Health affiliate, was constructing a new 274 bed hospital located in the Cathedral Hill District of San Francisco situated between Van Ness and Geary. The CPMC Van Ness and Geary Campus, was one of three top-of-the-line medical centers built in the heart of San Francisco. These next generation medical campuses are focused on serving local neighborhoods by providing easier access to healthcare services. The CPMC hospital is organized around comprehensive centers of care rather than traditional departments, enhancing the delivery of patient care while improving space efficiencies, workflow and productivity. The CPMC Van Ness and Geary hospital building is designed to meet LEED certification with the attached medical office meeting LEED Silver certification.

California Pacific Medical Center, a Sutter Health affiliate, was constructing a new 274 bed hospital located in the Cathedral Hill District of San Francisco situated between Van Ness and Geary. The CPMC Van Ness and Geary Campus, was one of three top-of-the-line medical centers built in the heart of San Francisco. These next generation medical campuses are focused on serving local neighborhoods by providing easier access to healthcare services. The CPMC hospital is organized around comprehensive centers of care rather than traditional departments, enhancing the delivery of patient care while improving space efficiencies, workflow and productivity. The CPMC Van Ness and Geary hospital building is designed to meet LEED certification with the attached medical office meeting LEED Silver certification.

Hospitals in general are noisy. Research has proven that a quiet hospital environment improves patient healing and medical staff satisfaction. The noise from equipment, patient intake and discharge areas, nursing stations, and common areas plus the regulatory requirements for patient privacy, makes having rooms designed to mitigate sound transmission a critical design. The General Contractor of Herrero Boldt Partners, Acoustical Consultants Shen Milsom and Wilke (SM&W), sub contractor California Drywall, Architect Smith Group and PABCO® Gypsum worked together to design the most cost effective medical facility that met the noise requirements designed for the project.

Measuring the Acoustical Design Options

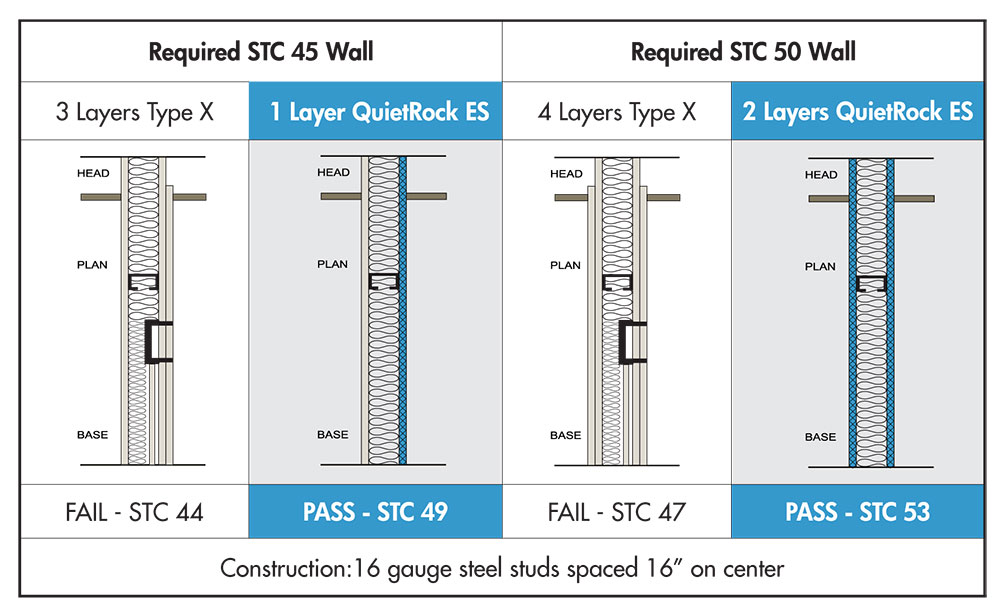

Certain walls within the hospital have specific noise control requirements that need to be achieved. The acoustical consultant on the project, Shen Milsom Wilke, wanted a more conservative design. After reviewing the QuietRock® product they requested an acoustic performance test of the walls by a NVLAP-accredited laboratory. Assemblies with multiple layers of standard type X and walls built with QuietRock EZ-SNAP® (ES) were tested in a controlled environment at Western Electro-Acoustic Laboratories (WEAL) for a fair and unbiased comparison.

The sound transmission between rooms – the amount of noise that would pass between rooms based on the proposed wall assemblies was a concern to the team. The hospital has different acoustical requirements for the walls: STC 40, 45 and 50. STC 40 walls can easily be achieved using traditional building materials. STC 45 walls are used between patient rooms and walls between bathrooms and public spaces. QuietRock was reserved for use in walls where higher performance is required.

STC 50 walls were specified for the following areas:

- Between a patient room and public space containing no door

- Partitions between an exam room and public space containing no door

- Walls around consultation rooms

- Partitions between exam or treatment rooms

- Walls between MRI rooms and public spaces

The initial STC 45 wall design specified the use of 3 layers of Type X gypsum and the STC 50 wall was designed to use 4 layers of Type X gypsum. However, a recent research study published in Sound and Vibration magazine indicated that 3 or 4 layers of gypsum may not be sufficient to achieve the required STC ratings for the hospital. The side-by-side testing performed at WEAL confirmed this assertion.

More Options with EZ-SNAP

In addition to designing for noise the integrated team also needed to address mold concerns. Breathing mold contaminated air can cause severe health effects to hospital patients, personnel and visitors. Because the campus buildings are equipped with HVAC units and plumbing running through ceilings, which may increase the risk for mold growth, QuietRock® ES Mold Resistant was used to treat areas above ceiling height. Places where mold is not a major concern, standard QuietRock® ES panels were installed to reduce costs while maintaining STC performance.

Installing gypsum panels horizontally in a “railroad” fashion is becoming a more common practice as builders look for creative ways to manage costs on the job. This technique of lining up panels horizontally on either side of the studs is believed to cut labor costs and decrease production time tables. Many builders railroad panels in corridors so that ductwork penetrations in the plenum spaces can be addressed more efficiently. Similarly, healthcare facilities prefer a railroaded install to accommodate wiring, plumbing and other devices into headwall fixtures.

Installing gypsum panels horizontally in a “railroad” fashion is becoming a more common practice as builders look for creative ways to manage costs on the job. This technique of lining up panels horizontally on either side of the studs is believed to cut labor costs and decrease production time tables. Many builders railroad panels in corridors so that ductwork penetrations in the plenum spaces can be addressed more efficiently. Similarly, healthcare facilities prefer a railroaded install to accommodate wiring, plumbing and other devices into headwall fixtures.

Not all gypsum products are approved for this type of an installation. QuietRock® has passed full fire and hose stream tests required for a railroad installation.

Advantage: QuietRock EZ-SNAP

Before any acoustic testing was done, Project Manager Matthew Boersma compared the costs of the gypsum walls to the walls built with QuietRock. Together HerreroBoldt, SM&W, California Drywall, and SmithGroup decided to use QuietRock ES based on a number of advantages.

- Replacing double layer of gypsum resulted in a reduction of 101,339 ft2 of gypsum delivered to the job site

- Reduced 13 truck deliveries to the job site

- Reduction of 178 carpenter man days on the job

- QuietRock® assemblies exceed the targeted STC rating

- Additional space due to fewer layers of gypsum for code required clearances

- Standard 7 ¼” door frame depth on 6” walls

- Less drywall screws needed to build assemblies

- Fewer multi-layer code inspections

- Six fewer 30yd dumpsters required to remove gypsum scrap

- Increased livable space in the building by 1,300 square feet by replacing the multi-layered gypsum walls with QuietRock® ES

“After completing our analysis, it was clear that QuietRock ES would be the best solution to achieve the required STC performance, at the lowest cost, for the Cathedral Hill district campus. Additionally, using QuietRock ES standardizes the wall dimensions and reduces variability for other in-wall systems like door frames and receptacle outlets.”

– Matthew Boersma, HerreroBoldt Partners