The Newsroom

How to Prevent and Repair Ridging, Beading and Cracking of Gypsum Panels

By Deborah Callaway

By Deborah Callaway

Manager, Technical Services

Gypsum is a very stable material with little shrinkage or expansion due to environmental conditions. However, framing, workmanship, building or structural movement can cause cracking, beading, or ridging of joints in gypsum panel assemblies.

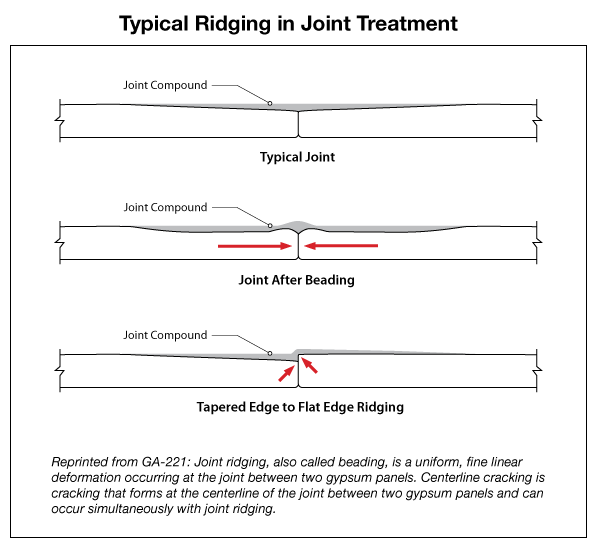

Centerline joint cracking occurs when movement causes adjacent gypsum panels to separate, and a crack appears in the joint finish. Joint beading or ridging is caused when movement forces adjacent gypsum panels together and a uniform “bump” appears on the joints.

This article explains how these various factors can affect gypsum panels, how to prevent these issues and how to repair them if they occur.

Wood Framing

Wood Framing

Wood framing changes dimensions as the moisture in the environment varies from season to season. When construction occurs in a cold, humid environment and the building is later occupied and heated, the structure dries out and the wood framing adjusts to the new, dryer environment by losing moisture resulting in shrinkage of the framing. This forces adjacent gypsum panels together, creating joint ridging or beading. The opposite occurs when the home is constructed in warm, dry weather, where the framing absorbs moisture and grows in the winter forcing adjacent gypsum panels to pull apart, causing joint cracking. These occurrences typically happen in the first year of building occupancy.

Building or Structural Movement

Building and structural movement can be caused by many factors, such as extreme weather. Flooding, earthquakes, high winds, extreme temperatures, and wild temperature shifts over a short period of time can cause movement of a structure that could result in joint cracking or ridging. Lack of control joints or expansion joints will also increase the likelihood of joint cracking or ridging.

Workmanship

Poor workmanship can also cause joint cracking or ridging. Foundations must be sound, framing must be true, and gypsum panels must be installed properly. The interior space must be properly conditioned prior to gypsum panel installation. Use of “belly bands” in walls should also be avoided.

Minimize Occurrences

The key to minimizing joint cracking or ridging are good construction practices. Aside from sound and true foundation and framing, installation of gypsum panels must follow industry guidelines, such as:

- Proper installation of gypsum panels, including conditioning of interior space as detailed in GA-216 Application and Finishing of Gypsum Panel Products

- Proper use of control joints as detailed in GA-234 Control Joints for Fire-Resistance Rated Systems

- Extreme weather tips and the use of belly bands, GA-236 Joint Treatment Under Extreme Weather Conditions and GA-255 Guidance on the Use of Panel “Rips”

- For ceiling applications, refer to GA-227 Recommendations for the Prevention of Ceiling Cracking

Repair

If joint cracking or ridging should occur, it is recommended that repairs wait for seasonal changes to moderate, typically, after a full year allowing for a heating and cooling cycle to complete.

More details on how to repair joint cracks and ridges can be found in GA-221 Causes, Prevention and Repair of Joint Ridging and Centerline Cracking.